Product

Precast Concrete Road Slab Manufacturer

Road Slab

Precast concrete road slabs are prefabricated offsite in controlled conditions and delivered to the job site fully cured and ready to be installed. Additionally, they can be designed for horizontal curves, utility-intensive pavement, airfield runways and taxiways. Jointed slabs are used singularly for isolated repairs or in multiples, to create a continuous surface of new pavement.

They are designed as rigid pavement system because the structure deflects very little under loading due to the high modulus of elasticity.

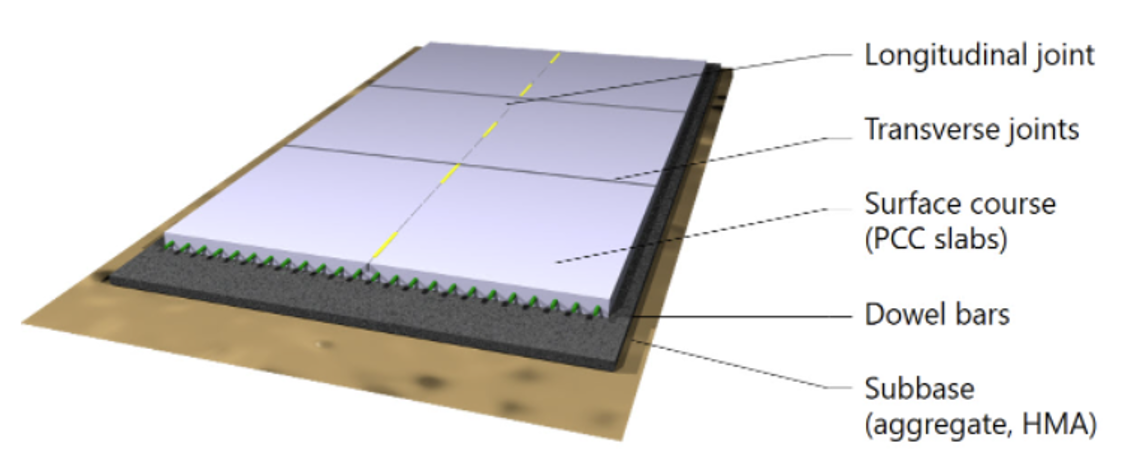

A typical rigid pavement structure consists of the surface course and the underlying base and subbase courses. The surface course (made of PCC) is the stiffest and provides the majority of strength. The underlying layers are orders of magnitude less stiff but still make important contributions to pavement strength as well as drainage. We provide a simple dowel system for joining road slabs along the transverse direction which is later grouted or slots to extrude high tension steel through which it is later post-tensioned and grouted.

- Grade: M40 -M60

Arto road slabs are cast using concrete with a low w/c ratio; it is poured into steel mechanized equipment called precast molds. Rebar is preplaced and secured inside the mould. Form vibrators are used to consolidate concrete to attain homogeneity and release any trapped air. The product is then stripped and the mould is reused. In the case of using post-tension, hollow piping is placed through the mould prior to pouring the concrete.

At every stage meticulous testing is done to maintain quality. Every concrete batch undergoes cube testing to ensure strength parameters are met along with slump testing to ensure consistence in the mix design. After demoulding the product goes through visual inspection to ensure no honey-combing, voids or cracks are present. In case any test fails the batch will be rejected.

Prepare the sublayers including subgrade, subbase and base course. This will require excavation, backfilling, compacting and levelling.

Once the subgrades are completed the precast road slabs can be placed and slotted into place. Followed by inserting post tension steel, stressing and grouting.

Gallery