Product

Precast Compound Wall Manufacturer

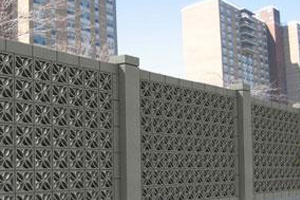

Compound Wall

Precast compound walls are a modular solution that can be used as boundary or security or architectural walls. Aesthetics, cost and speed of installation are some of the important factors considered in today’s construction environment. The modular design allows for variable height to suit the requirement and also allows for customisation of the design.

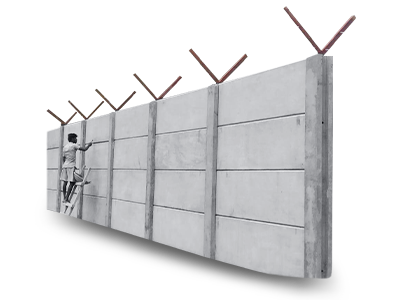

Designs are dependent on project specifications and applications. As these are non-structural members, they are designed to withstand dead and wind loads. We offer the option of using prestressed slabs to improve feasibility. Furthermore the addition of Steel Y-angles on top of the columns allow for the addition of barb wires for extra security. We also offer customised patterned slabs based on the customers’ requirements.

- Standard pole dimensions: 150mm x 150mm x 2400mm , 150mm x 150mm x 3000mm

- Standard slab dimensions: 1830mm x 300mm x 40mm (and 50mm) , 2500mm x 300mm x 50mm

Arto Compound Walls are cast using concrete with a low w/c ratio; it is poured into steel mechanized equipment called precast molds. Rebar is preplaced and secured inside the mould. Form vibrators are used to consolidate concrete to attain homogeneity and release any trapped air. The product is then stripped and the mould is reused. FRP sheets are used along with the mould to create customised patterns based on the customers’ requirements.

At every stage meticulous testing is done to maintain quality. Every concrete batch undergoes cube testing to ensure strength parameters are met along with slump testing to ensure consistence in the mix design. After demoulding the product goes through visual inspection to ensure no honey-combing, voids or cracks are present. In case any test fails the batch will be rejected.

First foundation is created based on soil parameters; either a pile foundation or eccentric foundation is cast on site after which the compound columns are placed and wet joined into the foundation. In some cases the column wall can be directly driven into the soil without the need for a foundation. Based on the topography of the land we can manufacture columns of varying height to help maintain the top level of the compound wall. Or add backfill to increase the ground level. Lastly the compound slabs are slid into place between the columns.

Based on requirement we can attach the compound wall to a retaining wall creating a monolithic structure that can both retain soil and provide a boundary wall.

Gallery