Precast concrete or In-situ concrete? It is a question constantly on the mind of a civil engineer working on commercial construction projects. The decision has to be made even before a project begins; to ensure faster, cheaper, and robust construction.

Precast concrete or In-situ concrete? It is a question constantly on the mind of a civil engineer working on commercial construction projects. The decision has to be made even before a project begins; to ensure faster, cheaper, and robust construction.

What is Precast Concrete?

Concrete that is cast in a controlled environment away from the site in reusable molds and then transported to the site ready to use right away is called Precast concrete.

Any construction component can be precast and brought to the site for assembly, be it slabs, beams, columns, staircases, culverts, footings, retaining walls, manholes; the list is endless.

Relevance of Precast Concrete Construction in India?

Though the Indian construction industry is valued at 500 million USD, it is observed that precast concrete construction takes up only 2% of the total share, and this method of construction is only limited to flyovers and bridges.

The rapid rise in the urban Indian population from 1901 to 2011 coupled with a 65 % shortage of labor force (Report by Ernst & Young and FICCI) has pushed the government to adopt the use of Precast Concrete Construction for large scale housing projects.

The need for good quality, speedy construction makes precast concrete the most viable option for the Indian construction industry.

What is In-situ concrete?

In situ concrete is transported from ready mix plants or prepared on-site, poured in site-specific forms, and cured on the construction site itself.

In situ concrete is best suited for large custom molds that cannot be easily transported and small-scale projects that cannot afford precast concrete.

It is more suited for earthquake-prone regions since the precast concrete components require more joints for their assembly.

Though in situ concrete is a prevalent form of concrete used for most construction projects, several disadvantages come with this type of construction.

- Though in situ concrete is a prevalent form of concrete used for most construction projects, several disadvantages come with this type of construction.

- In-situ concrete, once broken, cannot be replaced as easily as precast concrete.

- It is time-consuming since every process, from installing formworks, laying rebar, concrete mixing, casting, and curing, is done at the building site itself.

- The drying time is longer than for precast concrete, which can be inconvenient when building components with higher strengths because concrete gains strength slowly over time

Now let's look at how precast concrete is beneficial compared to in situ concrete.

Higher quality building components

All of the parameters that affect concrete quality, such as climatic conditions, moisture levels, aggregate and cement quality, water hardness, and even vibrations and compactions, are fully controlled, which helps manufacture the highest quality precast concrete components.

Cost-effective

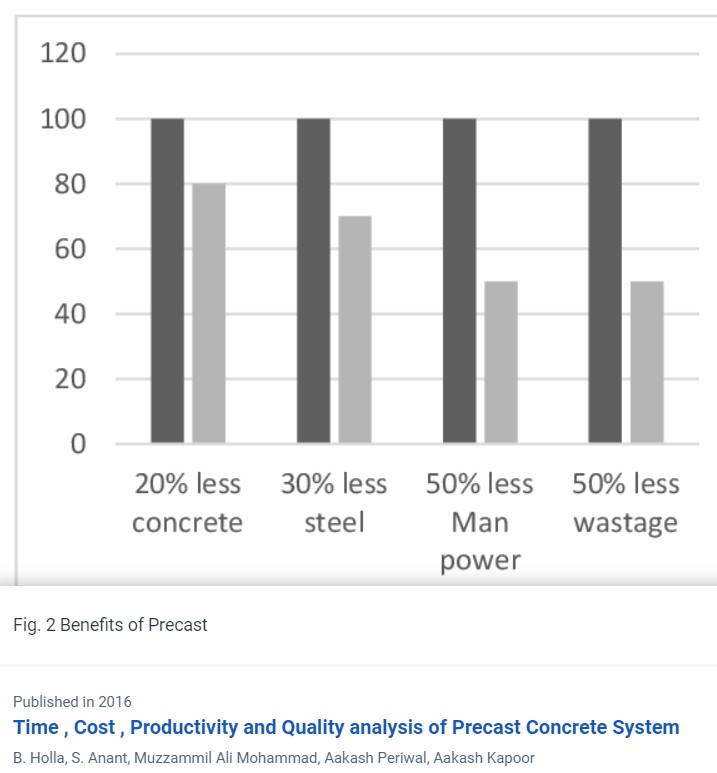

It requires a lot less labor force since components can be fabricated efficiently using assembly line techniques, thus drastically bringing down the costs. The best part is that you can reuse the components for other projects, adding to reducing the expenses.

Saves time

The precast components are ready to install, easier to assemble, and do not rely on intensive labor or climatic conditions, so construction is faster and saves a lot of time.

Better aesthetics

They have better surface finishing and need less preparation before applying paint, and wallpapers or other wall coverings can be applied directly without pre-preparation.

Elimination of site formwork

In situ concrete requires several formworks erected at the site that can be space, time, and labor-intensive, and installing their form works requires ideal weather conditions. Any slight delay can derail the project or overshoot the budget.

With precast concrete construction, you can avoid the entire coordination of labor and other logistics of site formwork.

Higher-strength

The precast concrete components are manufactured in a highly controlled environment, helping them withstand almost all the external stresses.

Thus, precast concrete produces safer and stronger components compared to in situ concrete.

Precast concrete is the future.

The new mantra for the modern construction industry is lower construction costs and faster project completion times, and precast concrete is the key to achieving this. With precast concrete’s versatility, affordability, ease of use, and superior quality products, it’s time for builders to consider using it for the majority of their commercial building projects.

Precast concrete, when used over in-situ concrete for construction, can be instrumental to solve the issues of quality, project delivery, strength, and safety and is the way forward for modernizing the construction industry